| DC BRUSHLESS | DC BRUSHED MOTOR | AC INDUCTION MOTOR | |

|---|---|---|---|

| Safety | Excellent | Excellent | Fair |

| High Torque | Excellent | Excellent | Poor |

| Long Life | Excellent | Poor | Fair |

| Easy Control | Excellent | Poor | Poor |

| Power Saving | Excellent | Fair | Poor |

| Low Maintenance | Excellent | Poor | Fair |

To aid correct motor roller selection please refer to the calculations below.

Divide the load weight (in Kg) by the minimum number of rollers under the load.

(Note any length is available – Table just shows convenient increments).

| Conveyor Width (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 |

|---|---|---|---|---|---|---|---|---|---|

| Load Limit per Roller (Kg) | 65 | 66 | 45 | 35 | 30 | 25 | 20 | 20 | 15 |

The maximum load on the motorised roller should not exceed the static load limit as specified in the table above.)

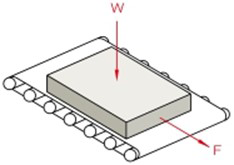

Necessary tangent direction for goods in movement is:

F = 9.8μW.

F: Necessary tangent direction force for goods in movement : F (N).

µ: Base friction coefficient of goods during movement (Please refer to Table 2).

W: Weight of goods in movement (Kg).

| Metal | Plastic | Timber | Good Quality Cardboard | Poor Quality Cardboard | Rubber |

|---|---|---|---|---|---|

| 0.015 | 0.03 | 0.05 | 0.065 | 0.09 | 0.2 |

Each jump belt from the motor roller takes some force and this needs to be added onto the required force to move the load.

| Transmission Type | Loss Per Jump Belt (Newtons) |

|---|---|

| Round Belt | 0.6 N |

| Poly V – 2 rib | 0.8 N |

| Poly V – 3 rib | 1.2 N |

So the tangential force required from the Motorised Roller equals: Force required to move the load + Force Lost in Drive Transmission = 9.8µW + (Loss per jump belt x No. of belts).

Weight of product to be handled: 20Kg.

Good Quality Cardboard Box: 40mm x 350mm x 100mm.

Roller Width: 400mm.

Roller Pitch: 75mm.

Zone Length: 600mm – Round belt drive (7 jump belts in zone).

(1) STATIC LOAD WEIGHT CALCULATION: 20Kg ÷ 5 rollers = 4Kg/roller.

From Table 1: 400mm rollers maximum load weight: 55Kg. So the load is ok on the roller.

(2) CALCULATION OF FORCE REQUIRED: F = 9.8 x µ x W = 9.8 x 0.065 x 20 = 12.74 N.

(3) FORCE LOST IN DRIVE TRANSMISSION: 7 x 0.6 = 4.2 N.

(4) HENCE: 12.74 + 4.2 = 16.94 N is the force required from the motorised roller.

Refer to the following pages to select a suitable motorised roller. From these we see, for this example, we can use a speed of 60 m/min (with 20.7 N force available) or a speed 18 m/min (with 70.4 N available) or a speed 100 m/min (17.4 N available).